Careers at Southern Fabrication Works

OPEN POSITIONS

Southern Fabrication Works is seeking a machinist. The machinist will set up and operate various machine tools to produce precision parts. This includes programming, setting up, and operating a computer numerical control (CNC) machine. May also fabricate and modify parts to make or repair machine tools or maintain industrial machines, applying knowledge of mechanics, mathematics, metal properties, layout, and machining procedures. The machinist will maintain quality and safety standards, keep records, and maintain equipment and supplies.

The machinist works under the specific supervision, guidance, and direction of the Machine Shop Foreman, and the general supervision of the owner.

Interested candidates will have a machining background, either education and/or practical experience will be able to multi-task in a fast-paced environment, have computer skills, a high level of communication and interpersonal skills.

The following is a minimal description of specific areas of accountability for a machinist:

- Calculate dimensions or tolerances, using instruments such as micrometers or vernier calipers.

- Machine parts to specifications, using machine tools, such as lathes, milling machines, shapers, or grinders.

- Set up, adjust, or operate basic or specialized machine tools used to perform precision machining operations.

- Measure, examine, or test completed units to check for defects and ensure conformance to specifications, using precision instruments, such as micrometers.

- Monitor the feed and speed of machines during the machining process.

- Study sample parts, blueprints, drawings, or engineering information to determine methods or sequences of operations needed to fabricate products.

- Diagnose machine tool malfunctions to determine need for adjustments or repairs.

- Confer with engineering, supervisory, or manufacturing personnel to exchange technical information.

- Operate single- or multiple-spindle drill presses to bore holes so that machining operations can be performed on metal or plastic workpieces.

- Plans machining by studying work orders, blueprints, engineering plans, materials, specifications, orthographic drawings, reference planes, locations of surfaces, and machining parameters, interpreting geometric dimensions and tolerances (GD&T).

- Plans stock inventory by checking stock to determine amount available; anticipating needed stock; placing and expediting orders for stock; verifying receipt of stock.

- Programs mills and lathes by entering instructions, including zero and reference points; setting tool registers, offsets, compensation, and conditional switches; calculating requirements, including basic math, geometry, and trigonometry; proving part programs.

- Sets-up mills and lathes; Verifies settings by measuring positions, first-run part, and sample workpieces.

- Maintains specifications by observing drilling, grooving, and cutting, including turning, facing, knurling and thread chasing operations; taking measurements; detecting malfunctions; troubleshooting processes; adjusting and reprogramming controls; sharpening and replacing worn tools; adhering to quality assurance procedures and processes.

- Maintains safe operations by adhering to safety procedures and regulations.

- Maintains equipment by completing preventive maintenance requirements; following manufacturer's instructions; troubleshooting malfunctions; calling for repairs.

- Accomplishes organization goals by accepting ownership for accomplishing new and different requests; exploring opportunities to add value to job accomplishments.

- Perform other miscellaneous duties as assigned through machine shop and/or fab shops.

Sales & Marketing Manager – Southern Fabrication Works, LLC seeks a sales mgr. w/ 4+ yrs. of exp. in sales management to negotiate & develop commercial partners/suppliers; deal with international suppliers/clients (mainly from BRA/MEX); lead sales & marketing teams; hire/train/evaluate team members; provide detailed/accurate sales forecasts; develop/execute international marketing strategies to meet consumer needs & maximize profits; analyze customer insights, consumer trends, market analysis, and marketing best practices to build successful strategies. Experience in industrial machinery and equipment manufacturing industry required. Job site: Burley, ID. Send CV to: nigel@southernfabricationworks.com,

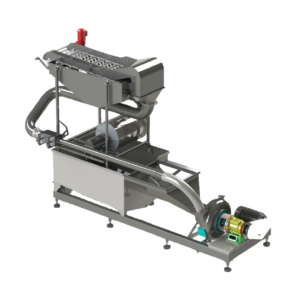

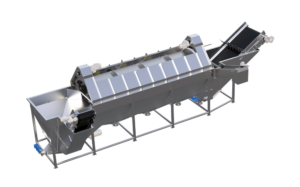

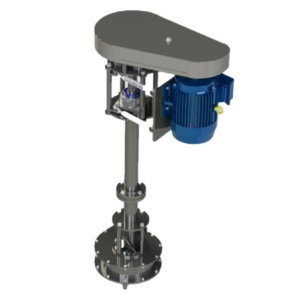

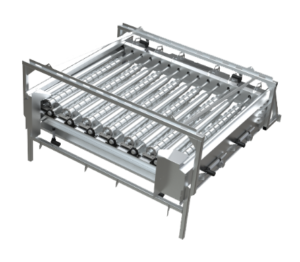

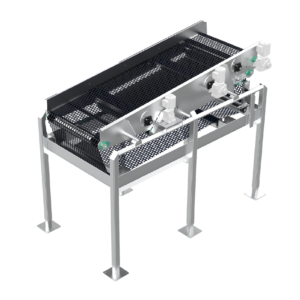

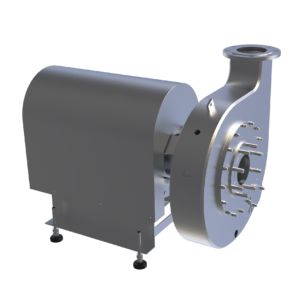

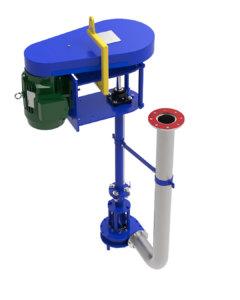

The Salesperson will work with customers to determine their needs, create solutions, and ensure a smooth sales process. This position will also be responsible for finding new sales leads in myriad ways, including, but not limited to, attending trade shows and business directories and following up with current clients, referrals, and cold calls. The Salesperson will work directly with the project manager, estimators, and engineering staff. Southern Fabrication Works (SFW) manufacturing capabilities include a full-service machine shop, a full-service fabrication shop, field crews, and an in-house engineering department. SFW’s overarching business focus is on the food processing industry, manufacturing food-grade equipment. We pride ourselves on the quality and expertise we bring to every project as we strive to become the standard by which excellence is measured.

ESSENTIAL FUNCTIONS

Reasonable accommodations may be made to enable individuals with disabilities to perform the position’s essential functions. The following statements are intended to describe the primary functions of the work. They should not be taken as an all-inclusive list of responsibilities, duties, and skills required of individuals assigned to this job.

- Generate new business by seeking out new customers as well as working with existing customers to determine their needs, create solutions, and ensure a smooth sales process

- Identify, research, and contact prospective customers and builds positive relationships that will generate future sales and repeat business.

- Resolve customer complaints regarding sales and service

- Contact regular and prospective customers to explain product features, build relationships, and solicit orders

- Recommend products to customers based on customers’ needs and interests

- Answer customers’ questions about products, prices, availability, product use, and scheduling

- Consult with clients after sales or contract signings to resolve problems and provide ongoing support

- Prepare drawings, estimates, and bids that meet specific customer needs

- Monitor market conditions, product innovations, and competitors’ products, prices, and sales

- Meet with customers to discuss their evolving needs and to assess the quality of our company’s relationship with them

- Negotiate details of contracts and order forms

- Support the Sales Manager on direct foreign sales and service outlets of an organization

- Advise customers and distributors on policies and operating procedures to ensure the functional effectiveness of business under the direction of the Sales Manager

- Visit franchised customers to stimulate interest in the establishment or expansion of equipment and technologies

- Promote product lines by attending industry events and expositions.

- Reach sales quotas and plan market strategies

- Other duties as assigned

COMPETENCIES

- Salesmanship and Charisma

- Ability to work independently as well as with others

- Presentation of information in group settings to a wide variety of audiences

- Stand/walk for prolonged periods

- Understand and carry out oral and written instruction

- Maintain accurate and detailed records

- Make common sense decisions in routine and critical situations

- Multi-task in a fast-paced environment

- Significant physical abilities include lifting/carrying/pushing/pulling, stooping/crouching, reaching/handling, talking/hearing conversations, and near/far visual acuity

- Strong interpersonal communication skills

- Ability to build and facilitate interpersonal relationships

- Proficient computer skills (Microsoft Office Suite), SAP, etc.

- Customer service

- Negotiation skills and ability to close business transactions

- Organization and attention to detail

- Excellent communication skills, both written and verbal, including facilitator skills. Strong digital literacy and technical proficiency

- Time management

- Analysis & Problem-solving skills

WORK ENVIRONMENT

This position operates in a professional office environment and a Manufacturing Facilities. This role routinely uses computers, photocopiers, and cell and landline phones. Stressful situations and frequent contact with Customers, employees, managers, contractors, and community members are to be expected.

REQUIRED QUALIFICATION

- · 3+ years of sales experience in the manufacturing industry or 5+ years of experience in a similar industry

- · High School Diploma or GED

- Exceptional customer service

- Excellent written and verbal communication skills. Experience presenting to large and diverse audiences.

- Experience with program planning, development, and implementation.

- Proficient computer skills (Microsoft Office Suite), SAP, etc.

- · Demonstrated history of developing business relationships and direct sales activities

- · Proven track record of delivering outstanding sales results through direct sales and distributor teams

- Experience coordinating and prioritizing tasks and duties in a team environment.

- · Good interpersonal skills, problem-solving skills, and the ability to handle confrontation

- · Basic to Intermediate Math Skills

- Negotiation skills and ability to close business transactions

PREFERRED QUALIFICATIONS

- Excellent written and verbal communication skills in both English and Spanish

- Outstanding organization and time management skills

- Proven track record of delivering outstanding sales results through direct sales and distributor teams

- Advanced MS Office suite skills, including Excel, Outlook, PowerPoint, Word, Teams, OneNote, and SharePoint

- Ability to assess problems and propose creative solutions, including the use of technology and innovative practices

- Experience supporting senior management in an area with organization-wide impact

- Demonstrated experience handling complex and delicate situations with tact and diplomacy

- Able to manage a high degree of complexity and distill information into simple messages, able to think strategically at a higher level and effectively develop critical processes.

- Excellent judgment, discretion, and unflappable under pressure.

- Ability to navigate ambiguity and work in a fast-changing environment with innovation and initiative and does not require heavy direction to achieve their daily goals successfully.

- An organized, detail-oriented, reliable, and proactive person looking for a role where they can learn from SFW’s leadership team.

ESSENTIAL PHYSICAL & MENTAL REQUIREMENTS

- Must be able to move throughout the facility transporting files and other items weighing up to 50 pounds frequently.

- Written and spoken communication skills require speaking, hearing, and seeing.

- Critical thinking and sound judgment are needed to follow legal processes and hospital policies.

MISSION STATEMENT

“To provide custom-built solutions from custom-engineered designs, all under one roof.”

EEO STATEMENT

Southern Fabrication Works provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, SFW complies with applicable state and local laws governing nondiscrimination. This policy applies to all terms and conditions of employment, or any form of workplace harassment based on race, color, religion, gender, sexual orientation, gender identity or expression, national origin, age, genetic information, disability, or veteran status. Improper interference with the ability of SWF’s employees to perform their job duties may result in discipline up to and including discharge.

Southern Fabrication Works is seeking Welders. Welders use hand-welding or flame-cutting equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products. Fits and welds or repairs as assortment of fixtures, weldments, sheet metal, machined castings, machined forgings, machined parts, and so on.

Welders works under the specific supervision, guidance, and direction of the Fabrication Shop and Production Managers, and the general supervision of the owner.

Interested candidates will be detailed oriented. Have two years’ experience TIG welding and be able to set up a welding machine by themselves. Candidates will have experience welding stainless steel.

The following is a minimal description of specific areas of accountability for a Welder:

- Welds a wide range of materials, i.e., iron, carbon steel, alloy steel, stainless steel, nonferrous metals, etc. using the G.T.A.W. process.

- Adjusts welding apparatus (select voltages, pressures, etc.).

- Performs set ups requiring aligning, blocking, and clamping of components to maintain specifications and avoid distortion.

- Has working knowledge of resistance, induction, stud, gas and automatic Tig welding.

- Sets up tooling and establishes parameters for all prototype and production jobs.

- Dimensionally inspects welds and other characteristics of parts being welded.

- Must have personal tools as required.

- Always maintains good housekeeping practices.

- Understands, implements, and maintains the company's quality policy in the performance of all duties and responsibilities.

- Weld components in flat, vertical, or overhead positions.

- Operate safety equipment and use safe work habits.

- Lay out, position, align, and secure parts and assemblies prior to assembly, using straightedges, combination squares, callipers, and rulers.

- Examine workpieces for defects and measure workpieces with straight edges or templates to ensure conformance with specifications.

- Recognize, set up, and operate hand and power tools common to the welding trade, such as shielded metal arc and gas metal arc welding equipment.

- Weld separately or in combination, using aluminium, stainless steel, cast iron, and other alloys.

- Clamp, hold, tack-weld, heat-bend, grind, or bolt component parts to obtain required configurations and positions for welding.

- Select and install torches, torch tips, filler rods, and flux, per welding chart specifications or types and thicknesses of metals.

- Determine required equipment and welding methods, applying knowledge of metallurgy, geometry, and welding techniques.

- Monitor the fitting, burning, and welding processes to avoid overheating of parts or warping, shrinking, distortion, or expansion of material.

- Operate manual or semi-automatic welding equipment to fuse metal segments, using processes such as gas tungsten arc, gas metal arc, flux-cored arc, plasma arc, shielded metal arc, resistance welding, and submerged arc welding.

- Analyse engineering drawings, blueprints, specifications, sketches, work orders, and material safety data sheets to plan layout, assembly, and welding operations.

- Mark or tag material with proper job number, piece marks, and other identifying marks as required.

- Other duties as assigned

Applications are available on our website: https://southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to hrmanager@southernfabricationworks.com

The Field Foreman is responsible for overseeing daily operations at a worksite to ensure the completion of projects safely and efficiently. Their duties include but are not limited to directing and facilitating the performance of specific tasks and monitoring budgets and labor hours to ensure the successful completion of projects within an allotted schedule and budget in collaboration with the Project Manager. The Field Foreman is also responsible for making sure all necessary tools and supplies for the job are readily available and ensuring all safety codes, laws, and regulations are being followed to maintain a safe work environment. They direct, supervise, and troubleshoot routine issues on the job site. They work closely with the management team to determine hiring needs, deadlines for specific tasks, and safety protocols to enforce among workers.

The projects are complex, time-consuming jobs that require attention to detail and precision. A successful Field Foreman will constantly plan for their crew's success by providing clear instructions on what they need at every step and ample training so everyone can do their part correctly.

ESSENTIAL FUNCTIONS

Reasonable accommodations may be made to enable individuals with disabilities to perform the position’s essential functions. The following statements are intended to describe the primary functions of the position. They should not be taken as an all-inclusive list of responsibilities, duties, and skills required of individuals assigned to this job.

- Coordinating daily tasks according to priorities and plans, making changes when necessary due to weather, supply, delivery, and personnel.

- Demonstrate Customer Obsession by ensuring the customers’ needs and expectations are a top priority for all team members.

- Promptly interpret blueprints, schematics, and drawings, and communicate them to the team.

- Handling customer relations in a professional and friendly manner

- Ability to modify and adjust equipment to accommodate the layout of the job site.

- Monitoring the attendance of the crew and tracking labor hours to ensure the appointed budget and labor hours are met.

- Delegating individual responsibilities and projects to crew members and contractors

- Facilitate the ongoing training and development of crew members.

- Ensuring all change orders are captured and reported to the project manager for accurate billing.

- Ensuring the quality of all jobs is aligned with SFW standards.

- Recruiting, training, managing, and mentoring employees and contractors

- Ensuring the utilization of best practices by constantly examining new and existing standard operating procedures against the current needs of the job

- Coordinating tools and resources needed on-site to complete the job.

- Ensuring the job site is cleaned at the end of each day and tools are adequately secured.

- Emphasizing safe use of tools, machinery, and equipment while providing training on safety gear and procedures

- Managing interpersonal relationships with customers and team members to earn and maintain their trust quickly.

- Regularly report project status to project managers, supervisors, site engineers, and other officials

COMPETENCIES

- Leadership

- High Level of Personal Accountability

- Excellent Communication Skills, both Written & Verbal

- Decisiveness

- Ability to Delegate Effectively

- Team Player

- Work Independently

- Organized and Detail Oriented

- Weld stainless steel to specific industry standards.

- Time Management

- Ability to use a computer.

- Analysis & Problem-solving skills

- Tools, machinery, and equipment knowledge

WORK ENVIRONMENT

This position mainly operates on job sites located in food processing facilities. This role routinely uses tools, heavy machinery, welding equipment, and cell phones. Frequent contact with customers, staff, vendors, contractors, and community members is expected.

REQUIRED QUALIFICATIONS

- A minimum of 3 years of experience in this position or five years of experience in a similar position

- Valid Driver’s License required.

- A deep understanding of welding principles

- Ability to perform Mig, tig, and stick welds on stainless steel.

- Motor Vehicle Record (MVR) must meet driving requirements set by On-Site Services

- Must have or be capable of obtaining a Class B commercial driving license.

- Good communication (oral, written, presentation)

- Pipe fitting & familiarity with controls

- Fitting- Pipe, Sanitary Tubing, Hydraulic

- Welding- TIG, MIG, Stick: Piping, Structural, Sheet Metal, Sanitary, and High Pressure

- Layout and Design- Sheet Metal, Structural

- Excellent leadership, organization, and time management skills

- Ability to interpret blueprints, schematics, and drawings.

- Ability to assess problems and propose creative solutions.

- Ability to work overtime when needed and around a changing schedule.

- An organized, detail-oriented, reliable, and proactive person looking for a role where they can learn from SFW’s leadership team.

PREFERRED QUALIFICATIONS

- GED, College Degree, or equivalent experience

- Advanced MS Office suite skills, including Excel, Outlook, PowerPoint, Word, Teams, OneNote, and SharePoint

- Excellent oral and written communication skills

ESSENTIAL PHYSICAL & MENTAL REQUIREMENTS

- Must be able to move around a job site transporting 60 pounds frequently.

- Written and spoken communication skills require speaking, hearing, and seeing.

- Critical thinking and sound judgment are needed.

MISSION STATEMENT

“To provide custom-built solutions from custom-engineered designs, all under one roof.”

EEO STATEMENT

Southern Fabrication Works provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, SFW complies with applicable state and local laws governing nondiscrimination. This policy applies to all terms and conditions of employment, or any form of workplace harassment based on race, color, religion, gender, sexual orientation, gender identity or expression, national origin, age, genetic information, disability, or veteran status. Improper interference with the ability of SWF’s employees to perform their job duties may result in discipline up to and including discharge.

Service Technician III is accountable for leading teams with daily operations and projects. They help with diagnosing problems and providing repair and service work. They must have the knowledge and ability to diagnose problems and be able to repair equipment, so it works correctly. Service Technician III will have more knowledge and experience than the other service techs. All of this must be done in accordance with the goals and overall vision of Southern Fabrication Works.

ESSENTIAL FUNCTIONS

Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions of the position. The following statements are intended to describe the major functions of the position and should not be taken as an all-inclusive list of responsibilities, duties, and skills required of individuals assigned to this job.

- Assist the service manager with tasks and projects.

- Direct crew members on how daily tasks need to be carried out.

- Be able to assess problems and provide solutions that cannot be answered by Service Tech I or II

- Help the manager coordinate the work of other employees.

- Help manage a small team of workers.

- Oversee the crew he is working with and ensure the work is done correctly.

- Ability to pipe fit and read blueprints.

- Making sure that all workers are following safety regulations and standards at job sites.

- Making sure that all workers have the training and right equipment for their jobs.

- Communicating with clients to make sure they are happy with the progress of the projects.

- Manage daily operations on site and make sure projects and tasks are done in a timely manner.

- Install and complete products while guaranteeing they work correctly and safely.

- Repair broken or damaged equipment.

- Interact with customers in a professional and friendly manner.

- Explaining complex installation, diagnostic, and repair issues in a way that’s accessible to a non-technical audience.

- Perform maintenance and provide customer support.

- Ability to work flexible hours and work around a changing schedule.

- Working knowledge of the equipment needed for the job.

- Escalate any issues to managers promptly.

- Be able to lift 50 lbs.

- Collaborates with managers and other service technicians.

- Utilize industry best practices, techniques, and standards throughout the entire project execution.

- Other duties as assigned.

COMPETENCIES

- Leadership

- High Level of Personal Accountability

- Excellent Communication Skills, both Written & Verbal

- Decisiveness

- Ability to Delegate Effectively

- Team Player

- Work Independently

- Organized and Detail Oriented

- Time Management

- Analysis & Problem-solving skills

WORK ENVIRONMENT

This position operates on job sites, mainly food processing and manufacturing facilities which can be wet& noisy. This role routinely uses heavy equipment, mechanical tools, computers, photocopiers, and cell phones. Frequent contact with contractors, vendors, and community members is expected.

REQUIRED QUALIFICATIONS

- Basic use of hand and power tools, mechanical aptitude, and problem solver

- Experience in mechanics, service work, project coordination/management, construction management, or other relevant experience

- Welding- TIG, MIG, Stick: Piping, Structural, Sheet Metal, Sanitary, and High Pressure

- Pipe fitting & familiarity with controls

- Good communication (oral, written, presentation), interpersonal, negotiation, and organizational skills.

- Excellent leadership, organization, and time management skills

- An organized, detail-oriented, reliable, and proactive person looking for a role where they can learn from SFW’s leadership team.

PREFERRED QUALIFICATIONS

- GED, High School diploma, College Degree, or equivalent experience

- Good oral and written communication skills (Spanish a plus)

- Pipe fitting & familiarity with controls

- Fitting- Pipe, Sanitary Tubing, Hydraulic

- Layout and Design- Sheet Metal, Structural

ESSENTIAL PHYSICAL & MENTAL REQUIREMENTS

- Must be able to move throughout the job sites transporting tools and other items weighing up to 50 pounds on a frequent basis.

- Written and spoken communication skills require the ability to speak, hear and see.

- Critical thinking and sound judgment are needed to follow legal processes and Company policies.

MISSION STATEMENT

“To provide custom-built solutions from custom-engineered designs, all under one roof.”

EEO STATEMENT

Southern Fabrication Works provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, SFW complies with applicable state and local laws governing nondiscrimination. This policy applies to all terms and conditions of employment, or any form of workplace harassment based on race, color, religion, gender, sexual orientation, gender identity or expression, national origin, age, genetic information, disability, or veteran status. Improper interference with the ability of SWF’s employees to perform their job duties may result in discipline up to and including discharge.

Southern Fabrication Works, LLC is located in Burley, Idaho where we design and construct custom food processing equipment. We are currently seeking a receptionist. The receptionist is the first point of contact for our company. Responsibilities include, but are not limited to, offering administrative support, welcome guests and greet people who come into the business, answering phones and redirecting calls, and assisting with payroll and accounts receivable.

The Receptionist works under the specific supervision, guidance, and direction of the controllers, and the general supervision of the Owner.

Interested candidates will have experience as a receptionist, from office representative, or similar, ability to multi-task in a fast-paced environment, and a high level of communication and interpersonal skills.

The following is a minimal description of specific areas of accountability for the Receptionist:

- Greet and welcome guests as soon as they arrive at the office

- Direct visitors to the appropriate person and office

- Answer, screen, and forward incoming phone calls

- Receive, sort, and distribute daily mail

- Update calendars and schedule meetings as needed

- Maintain facility security by following safety procedures and controlling access via the reception desk (monitor logbook, page individuals to the front office to meet with guests, etc.)

- Accept payments from walk-in customers and oversee petty cash

- Enter payroll and job time weekly

- Assist the Finance Department with invoicing and other tasks

- Other duties as assigned

Southern Fabrication Works, LLC is located in Burley, Idaho where we design and construct custom food processing equipment. We are currently seeking a Parts Room Attendant. The parts room attendant ensures that the parts room remains stocked and organized. This position plays a key role in inventory, LTL shipping, and safety. The parts room attendant will assist co-workers by checking out equipment and materials needed for them to perform their job, ensured equipment works properly and is safe. The ideal candidate feels a sense of responsibility and ownership for how the parts room looks and operates and works with a level of pride and integrity.

The parts room attendant works under the specific supervision, guidance, and direction of the Operations Manager, and the general supervision of the Owner.

Interested candidates will have experience stocking shelves, shipping, logistics, and a general background and understanding of welding.

The following is a minimal description of specific areas of accountability for a Parts Room Attendant:

- Record inventory data manually or on a computer

- Document discrepancies between inventory records and physical counts of stock

- Receive, count, and verify incoming orders

- Pack and unpack items for storage in parts room and/or warehouse

- Operate machinery for moving stock items

- Process LTL shipping requests, requisitions, or purchase orders

- Distribute products or materials to co-workers and/or customers

- Assist and direct other parts room employees in their daily duties

- Coordinate with co-workers to accomplish large tasks efficiently

- Keep parts room neat and orderly

- Maintain an accurate log of all equipment checked out of the parts room to each employee

- Inspect all equipment before it leaves the parts room and when it returns to ensure it is in good condition and properly labeled

- Keep SDS binders updated

- Properly label all bottles to comply with Hazard Communication Standard

- Research replacement prices for damaged, lost, or stollen equipment

- Provide backup for the parts runner

- Other duties as assigned

Applications are available on our website: https://www.southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to timbri@southernfabricationworks.com.

Southern Fabrication Works is seeking a Salesperson. The Salesperson will sell food processing systems and services to customer. The Salesperson will work with customers to find what they want, create solutions, and ensure a smooth sales process. This position will also be responsible for finding new sales leads through a myriad of ways including, but not limited to, attending trade shows, business directories, following up with current clients, referrals, and cold calls.

The Salesperson works under the specific supervision, guidance, and direction of the Sales Manager, and the general supervision of the owner. The Salesperson will also work directly with the project manager to determine timetables for any given project, as well as the estimators, ensuring they have the required information needed to quote the job. The Salesperson also works with the engineering team to draft customized products which will meet the needs of the customer.

Interested candidates will have a proven track record of delivering outstanding sales results by building rapport with clients and/or potential clients, determining their need, and successfully closing a sale. Ideal candidates will have five (5) or more years experience in sales, with a manufacturing background, and at least two (2) years related experience in the food industry.

The following is a minimal description of specific areas of accountability for a Salesperson:

- Resolve customer complaints regarding sales and service.

- Contact regular and prospective customers to explain product features, build relationships, and solicit orders.

- Recommend products to customers, based on customers’ needs and interests.

- Answer customers’ questions about products, prices, availability, product use, and scheduling.

- Consult with clients after sales or contract signings to resolve problems and to provide ongoing support.

- Prepare drawings, estimates, and bids that meet specific customer needs.

- Monitor market conditions, product innovations, and competitors’ products, prices, and sales.

- Meet with customers to discuss their evolving needs and to assess the quality of our company’s relationship with them.

- Negotiate details of contracts and order forms.

- Support the Sales Manager on direct foreign sales and service outlets of an organization.

- Advise dealers and distributors on policies and operating procedures to ensure functional effectiveness of business under the direction of the Sales Manager.

- Visit franchised dealers to stimulate interest in establishment or expansion programs.

- Identifies, researches, and contacts prospective customers and builds positive relationships that will generate future sales and repeat business.

- Promote product lines by attending industry events and expositions.

- Proven ability to develop business relationships and direct sales activities

- Establish sales quotas and plan market strategies

- Proven track record of delivering outstanding sales results through direct sales and distributor teams

- Other duties as assigned

Applications are available on our website: https://www.southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to timbri@southernfabricationworks.com.

Southern Fabrication Works is seeking a machinist. The machinist will set up and operate various machine tools to produce precision parts. This includes programming, setting up, and operating a computer numerical control (CNC) machine. May also fabricate and modify parts to make or repair machine tools or maintain industrial machines, applying knowledge of mechanics, mathematics, metal properties, layout, and machining procedures. The machinist will maintain quality and safety standards, keep records, and maintain equipment and supplies.

The machinist works under the specific supervision, guidance, and direction of the Machine Shop Foreman, and the general supervision of the owner.

Interested candidates will have a machining background, either education and/or practical experience will be able to multi-task in a fast-paced environment, have computer skills, a high level of communication and interpersonal skills.

The following is a minimal description of specific areas of accountability for a machinist:

- Calculate dimensions or tolerances, using instruments such as micrometers or vernier calipers.

- Machine parts to specifications, using machine tools, such as lathes, milling machines, shapers, or grinders.

- Set up, adjust, or operate basic or specialized machine tools used to perform precision machining operations.

- Measure, examine, or test completed units to check for defects and ensure conformance to specifications, using precision instruments, such as micrometers.

- Monitor the feed and speed of machines during the machining process.

- Study sample parts, blueprints, drawings, or engineering information to determine methods or sequences of operations needed to fabricate products.

- Diagnose machine tool malfunctions to determine need for adjustments or repairs.

- Confer with engineering, supervisory, or manufacturing personnel to exchange technical information.

- Operate single- or multiple-spindle drill presses to bore holes so that machining operations can be performed on metal or plastic workpieces.

- Plans machining by studying work orders, blueprints, engineering plans, materials, specifications, orthographic drawings, reference planes, locations of surfaces, and machining parameters, interpreting geometric dimensions and tolerances (GD&T).

- Plans stock inventory by checking stock to determine amount available; anticipating needed stock; placing and expediting orders for stock; verifying receipt of stock.

- Programs mills and lathes by entering instructions, including zero and reference points; setting tool registers, offsets, compensation, and conditional switches; calculating requirements, including basic math, geometry, and trigonometry; proving part programs.

- Sets-up mills and lathes; Verifies settings by measuring positions, first-run part, and sample workpieces.

- Maintains specifications by observing drilling, grooving, and cutting, including turning, facing, knurling and thread chasing operations; taking measurements; detecting malfunctions; troubleshooting processes; adjusting and reprogramming controls; sharpening and replacing worn tools; adhering to quality assurance procedures and processes.

- Maintains safe operations by adhering to safety procedures and regulations.

- Maintains equipment by completing preventive maintenance requirements; following manufacturer's instructions; troubleshooting malfunctions; calling for repairs.

- Accomplishes organization goals by accepting ownership for accomplishing new and different requests; exploring opportunities to add value to job accomplishments.

- Perform other miscellaneous duties as assigned through machine shop and/or fab shops.

The Salesperson will work with customers to determine their needs, create solutions, and ensure a smooth sales process. This position will also be responsible for finding new sales leads in myriad ways, including, but not limited to, attending trade shows and business directories and following up with current clients, referrals, and cold calls. The Salesperson will work directly with the project manager, estimators, and engineering staff. Southern Fabrication Works (SFW) manufacturing capabilities include a full-service machine shop, a full-service fabrication shop, field crews, and an in-house engineering department. SFW’s overarching business focus is on the food processing industry, manufacturing food-grade equipment. We pride ourselves on the quality and expertise we bring to every project as we strive to become the standard by which excellence is measured.

ESSENTIAL FUNCTIONS

Reasonable accommodations may be made to enable individuals with disabilities to perform the position’s essential functions. The following statements are intended to describe the primary functions of the work. They should not be taken as an all-inclusive list of responsibilities, duties, and skills required of individuals assigned to this job.

- Generate new business by seeking out new customers as well as working with existing customers to determine their needs, create solutions, and ensure a smooth sales process

- Identify, research, and contact prospective customers and builds positive relationships that will generate future sales and repeat business.

- Resolve customer complaints regarding sales and service

- Contact regular and prospective customers to explain product features, build relationships, and solicit orders

- Recommend products to customers based on customers’ needs and interests

- Answer customers’ questions about products, prices, availability, product use, and scheduling

- Consult with clients after sales or contract signings to resolve problems and provide ongoing support

- Prepare drawings, estimates, and bids that meet specific customer needs

- Monitor market conditions, product innovations, and competitors’ products, prices, and sales

- Meet with customers to discuss their evolving needs and to assess the quality of our company’s relationship with them

- Negotiate details of contracts and order forms

- Support the Sales Manager on direct foreign sales and service outlets of an organization

- Advise customers and distributors on policies and operating procedures to ensure the functional effectiveness of business under the direction of the Sales Manager

- Visit franchised customers to stimulate interest in the establishment or expansion of equipment and technologies

- Promote product lines by attending industry events and expositions.

- Reach sales quotas and plan market strategies

- Other duties as assigned

COMPETENCIES

- Salesmanship and Charisma

- Ability to work independently as well as with others

- Presentation of information in group settings to a wide variety of audiences

- Stand/walk for prolonged periods

- Understand and carry out oral and written instruction

- Maintain accurate and detailed records

- Make common sense decisions in routine and critical situations

- Multi-task in a fast-paced environment

- Significant physical abilities include lifting/carrying/pushing/pulling, stooping/crouching, reaching/handling, talking/hearing conversations, and near/far visual acuity

- Strong interpersonal communication skills

- Ability to build and facilitate interpersonal relationships

- Proficient computer skills (Microsoft Office Suite), SAP, etc.

- Customer service

- Negotiation skills and ability to close business transactions

- Organization and attention to detail

- Excellent communication skills, both written and verbal, including facilitator skills. Strong digital literacy and technical proficiency

- Time management

- Analysis & Problem-solving skills

WORK ENVIRONMENT

This position operates in a professional office environment and a Manufacturing Facilities. This role routinely uses computers, photocopiers, and cell and landline phones. Stressful situations and frequent contact with Customers, employees, managers, contractors, and community members are to be expected.

REQUIRED QUALIFICATION

- · 3+ years of sales experience in the manufacturing industry or 5+ years of experience in a similar industry

- · High School Diploma or GED

- Exceptional customer service

- Excellent written and verbal communication skills. Experience presenting to large and diverse audiences.

- Experience with program planning, development, and implementation.

- Proficient computer skills (Microsoft Office Suite), SAP, etc.

- · Demonstrated history of developing business relationships and direct sales activities

- · Proven track record of delivering outstanding sales results through direct sales and distributor teams

- Experience coordinating and prioritizing tasks and duties in a team environment.

- · Good interpersonal skills, problem-solving skills, and the ability to handle confrontation

- · Basic to Intermediate Math Skills

- Negotiation skills and ability to close business transactions

PREFERRED QUALIFICATIONS

- Excellent written and verbal communication skills in both English and Spanish

- Outstanding organization and time management skills

- Proven track record of delivering outstanding sales results through direct sales and distributor teams

- Advanced MS Office suite skills, including Excel, Outlook, PowerPoint, Word, Teams, OneNote, and SharePoint

- Ability to assess problems and propose creative solutions, including the use of technology and innovative practices

- Experience supporting senior management in an area with organization-wide impact

- Demonstrated experience handling complex and delicate situations with tact and diplomacy

- Able to manage a high degree of complexity and distill information into simple messages, able to think strategically at a higher level and effectively develop critical processes.

- Excellent judgment, discretion, and unflappable under pressure.

- Ability to navigate ambiguity and work in a fast-changing environment with innovation and initiative and does not require heavy direction to achieve their daily goals successfully.

- An organized, detail-oriented, reliable, and proactive person looking for a role where they can learn from SFW’s leadership team.

ESSENTIAL PHYSICAL & MENTAL REQUIREMENTS

- Must be able to move throughout the facility transporting files and other items weighing up to 50 pounds frequently.

- Written and spoken communication skills require speaking, hearing, and seeing.

- Critical thinking and sound judgment are needed to follow legal processes and hospital policies.

MISSION STATEMENT

“To provide custom-built solutions from custom-engineered designs, all under one roof.”

EEO STATEMENT

Southern Fabrication Works provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, SFW complies with applicable state and local laws governing nondiscrimination. This policy applies to all terms and conditions of employment, or any form of workplace harassment based on race, color, religion, gender, sexual orientation, gender identity or expression, national origin, age, genetic information, disability, or veteran status. Improper interference with the ability of SWF’s employees to perform their job duties may result in discipline up to and including discharge.

Southern Fabrication Works is seeking Welders. Welders use hand-welding or flame-cutting equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products. Fits and welds or repairs as assortment of fixtures, weldments, sheet metal, machined castings, machined forgings, machined parts, and so on.

Welders works under the specific supervision, guidance, and direction of the Fabrication Shop and Production Managers, and the general supervision of the owner.

Interested candidates will be detailed oriented. Have two years’ experience TIG welding and be able to set up a welding machine by themselves. Candidates will have experience welding stainless steel.

The following is a minimal description of specific areas of accountability for a Welder:

- Welds a wide range of materials, i.e., iron, carbon steel, alloy steel, stainless steel, nonferrous metals, etc. using the G.T.A.W. process.

- Adjusts welding apparatus (select voltages, pressures, etc.).

- Performs set ups requiring aligning, blocking, and clamping of components to maintain specifications and avoid distortion.

- Has working knowledge of resistance, induction, stud, gas and automatic Tig welding.

- Sets up tooling and establishes parameters for all prototype and production jobs.

- Dimensionally inspects welds and other characteristics of parts being welded.

- Must have personal tools as required.

- Always maintains good housekeeping practices.

- Understands, implements, and maintains the company's quality policy in the performance of all duties and responsibilities.

- Weld components in flat, vertical, or overhead positions.

- Operate safety equipment and use safe work habits.

- Lay out, position, align, and secure parts and assemblies prior to assembly, using straightedges, combination squares, callipers, and rulers.

- Examine workpieces for defects and measure workpieces with straight edges or templates to ensure conformance with specifications.

- Recognize, set up, and operate hand and power tools common to the welding trade, such as shielded metal arc and gas metal arc welding equipment.

- Weld separately or in combination, using aluminium, stainless steel, cast iron, and other alloys.

- Clamp, hold, tack-weld, heat-bend, grind, or bolt component parts to obtain required configurations and positions for welding.

- Select and install torches, torch tips, filler rods, and flux, per welding chart specifications or types and thicknesses of metals.

- Determine required equipment and welding methods, applying knowledge of metallurgy, geometry, and welding techniques.

- Monitor the fitting, burning, and welding processes to avoid overheating of parts or warping, shrinking, distortion, or expansion of material.

- Operate manual or semi-automatic welding equipment to fuse metal segments, using processes such as gas tungsten arc, gas metal arc, flux-cored arc, plasma arc, shielded metal arc, resistance welding, and submerged arc welding.

- Analyse engineering drawings, blueprints, specifications, sketches, work orders, and material safety data sheets to plan layout, assembly, and welding operations.

- Mark or tag material with proper job number, piece marks, and other identifying marks as required.

- Other duties as assigned

Applications are available on our website: https://southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to hrmanager@southernfabricationworks.com

The Field Foreman is responsible for overseeing daily operations at a worksite to ensure the completion of projects safely and efficiently. Their duties include but are not limited to directing and facilitating the performance of specific tasks and monitoring budgets and labor hours to ensure the successful completion of projects within an allotted schedule and budget in collaboration with the Project Manager. The Field Foreman is also responsible for making sure all necessary tools and supplies for the job are readily available and ensuring all safety codes, laws, and regulations are being followed to maintain a safe work environment. They direct, supervise, and troubleshoot routine issues on the job site. They work closely with the management team to determine hiring needs, deadlines for specific tasks, and safety protocols to enforce among workers.

The projects are complex, time-consuming jobs that require attention to detail and precision. A successful Field Foreman will constantly plan for their crew's success by providing clear instructions on what they need at every step and ample training so everyone can do their part correctly.

ESSENTIAL FUNCTIONS

Reasonable accommodations may be made to enable individuals with disabilities to perform the position’s essential functions. The following statements are intended to describe the primary functions of the position. They should not be taken as an all-inclusive list of responsibilities, duties, and skills required of individuals assigned to this job.

- Coordinating daily tasks according to priorities and plans, making changes when necessary due to weather, supply, delivery, and personnel.

- Demonstrate Customer Obsession by ensuring the customers’ needs and expectations are a top priority for all team members.

- Promptly interpret blueprints, schematics, and drawings, and communicate them to the team.

- Handling customer relations in a professional and friendly manner

- Ability to modify and adjust equipment to accommodate the layout of the job site.

- Monitoring the attendance of the crew and tracking labor hours to ensure the appointed budget and labor hours are met.

- Delegating individual responsibilities and projects to crew members and contractors

- Facilitate the ongoing training and development of crew members.

- Ensuring all change orders are captured and reported to the project manager for accurate billing.

- Ensuring the quality of all jobs is aligned with SFW standards.

- Recruiting, training, managing, and mentoring employees and contractors

- Ensuring the utilization of best practices by constantly examining new and existing standard operating procedures against the current needs of the job

- Coordinating tools and resources needed on-site to complete the job.

- Ensuring the job site is cleaned at the end of each day and tools are adequately secured.

- Emphasizing safe use of tools, machinery, and equipment while providing training on safety gear and procedures

- Managing interpersonal relationships with customers and team members to earn and maintain their trust quickly.

- Regularly report project status to project managers, supervisors, site engineers, and other officials

COMPETENCIES

- Leadership

- High Level of Personal Accountability

- Excellent Communication Skills, both Written & Verbal

- Decisiveness

- Ability to Delegate Effectively

- Team Player

- Work Independently

- Organized and Detail Oriented

- Weld stainless steel to specific industry standards.

- Time Management

- Ability to use a computer.

- Analysis & Problem-solving skills

- Tools, machinery, and equipment knowledge

WORK ENVIRONMENT

This position mainly operates on job sites located in food processing facilities. This role routinely uses tools, heavy machinery, welding equipment, and cell phones. Frequent contact with customers, staff, vendors, contractors, and community members is expected.

REQUIRED QUALIFICATIONS

- A minimum of 3 years of experience in this position or five years of experience in a similar position

- Valid Driver’s License required.

- A deep understanding of welding principles

- Ability to perform Mig, tig, and stick welds on stainless steel.

- Motor Vehicle Record (MVR) must meet driving requirements set by On-Site Services

- Must have or be capable of obtaining a Class B commercial driving license.

- Good communication (oral, written, presentation)

- Pipe fitting & familiarity with controls

- Fitting- Pipe, Sanitary Tubing, Hydraulic

- Welding- TIG, MIG, Stick: Piping, Structural, Sheet Metal, Sanitary, and High Pressure

- Layout and Design- Sheet Metal, Structural

- Excellent leadership, organization, and time management skills

- Ability to interpret blueprints, schematics, and drawings.

- Ability to assess problems and propose creative solutions.

- Ability to work overtime when needed and around a changing schedule.

- An organized, detail-oriented, reliable, and proactive person looking for a role where they can learn from SFW’s leadership team.

PREFERRED QUALIFICATIONS

- GED, College Degree, or equivalent experience

- Advanced MS Office suite skills, including Excel, Outlook, PowerPoint, Word, Teams, OneNote, and SharePoint

- Excellent oral and written communication skills

ESSENTIAL PHYSICAL & MENTAL REQUIREMENTS

- Must be able to move around a job site transporting 60 pounds frequently.

- Written and spoken communication skills require speaking, hearing, and seeing.

- Critical thinking and sound judgment are needed.

MISSION STATEMENT

“To provide custom-built solutions from custom-engineered designs, all under one roof.”

EEO STATEMENT

Southern Fabrication Works provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, SFW complies with applicable state and local laws governing nondiscrimination. This policy applies to all terms and conditions of employment, or any form of workplace harassment based on race, color, religion, gender, sexual orientation, gender identity or expression, national origin, age, genetic information, disability, or veteran status. Improper interference with the ability of SWF’s employees to perform their job duties may result in discipline up to and including discharge.

Service Technician III is accountable for leading teams with daily operations and projects. They help with diagnosing problems and providing repair and service work. They must have the knowledge and ability to diagnose problems and be able to repair equipment, so it works correctly. Service Technician III will have more knowledge and experience than the other service techs. All of this must be done in accordance with the goals and overall vision of Southern Fabrication Works.

ESSENTIAL FUNCTIONS

Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions of the position. The following statements are intended to describe the major functions of the position and should not be taken as an all-inclusive list of responsibilities, duties, and skills required of individuals assigned to this job.

- Assist the service manager with tasks and projects.

- Direct crew members on how daily tasks need to be carried out.

- Be able to assess problems and provide solutions that cannot be answered by Service Tech I or II

- Help the manager coordinate the work of other employees.

- Help manage a small team of workers.

- Oversee the crew he is working with and ensure the work is done correctly.

- Ability to pipe fit and read blueprints.

- Making sure that all workers are following safety regulations and standards at job sites.

- Making sure that all workers have the training and right equipment for their jobs.

- Communicating with clients to make sure they are happy with the progress of the projects.

- Manage daily operations on site and make sure projects and tasks are done in a timely manner.

- Install and complete products while guaranteeing they work correctly and safely.

- Repair broken or damaged equipment.

- Interact with customers in a professional and friendly manner.

- Explaining complex installation, diagnostic, and repair issues in a way that’s accessible to a non-technical audience.

- Perform maintenance and provide customer support.

- Ability to work flexible hours and work around a changing schedule.

- Working knowledge of the equipment needed for the job.

- Escalate any issues to managers promptly.

- Be able to lift 50 lbs.

- Collaborates with managers and other service technicians.

- Utilize industry best practices, techniques, and standards throughout the entire project execution.

- Other duties as assigned.

COMPETENCIES

- Leadership

- High Level of Personal Accountability

- Excellent Communication Skills, both Written & Verbal

- Decisiveness

- Ability to Delegate Effectively

- Team Player

- Work Independently

- Organized and Detail Oriented

- Time Management

- Analysis & Problem-solving skills

WORK ENVIRONMENT

This position operates on job sites, mainly food processing and manufacturing facilities which can be wet& noisy. This role routinely uses heavy equipment, mechanical tools, computers, photocopiers, and cell phones. Frequent contact with contractors, vendors, and community members is expected.

REQUIRED QUALIFICATIONS

- Basic use of hand and power tools, mechanical aptitude, and problem solver

- Experience in mechanics, service work, project coordination/management, construction management, or other relevant experience

- Welding- TIG, MIG, Stick: Piping, Structural, Sheet Metal, Sanitary, and High Pressure

- Pipe fitting & familiarity with controls

- Good communication (oral, written, presentation), interpersonal, negotiation, and organizational skills.

- Excellent leadership, organization, and time management skills

- An organized, detail-oriented, reliable, and proactive person looking for a role where they can learn from SFW’s leadership team.

PREFERRED QUALIFICATIONS

- GED, High School diploma, College Degree, or equivalent experience

- Good oral and written communication skills (Spanish a plus)

- Pipe fitting & familiarity with controls

- Fitting- Pipe, Sanitary Tubing, Hydraulic

- Layout and Design- Sheet Metal, Structural

ESSENTIAL PHYSICAL & MENTAL REQUIREMENTS

- Must be able to move throughout the job sites transporting tools and other items weighing up to 50 pounds on a frequent basis.

- Written and spoken communication skills require the ability to speak, hear and see.

- Critical thinking and sound judgment are needed to follow legal processes and Company policies.

MISSION STATEMENT

“To provide custom-built solutions from custom-engineered designs, all under one roof.”

EEO STATEMENT

Southern Fabrication Works provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability, or genetics. In addition to federal law requirements, SFW complies with applicable state and local laws governing nondiscrimination. This policy applies to all terms and conditions of employment, or any form of workplace harassment based on race, color, religion, gender, sexual orientation, gender identity or expression, national origin, age, genetic information, disability, or veteran status. Improper interference with the ability of SWF’s employees to perform their job duties may result in discipline up to and including discharge.

Southern Fabrication Works, LLC is located in Burley, Idaho where we design and construct custom food processing equipment. We are currently seeking a Laser Operator. The laser operator will primarily operate our laser, cutting sheets of stainless steel into various parts, deburring the parts, and then ensuring they are put in the proper kitting box. Detail oriented, highly accurate, and the ability to communicate with coworkers, and management, as well as the ability to multitask and meet deadlines are essential.

The laser operator works under the specific supervision, guidance, and direction of the Pre-Fabrication Manager, and the general supervision of the Owner.

Interested candidates will have experience operating a laser, along with other power and hand tools, can accurately and precisely read a tape measure, and can read and understand blueprints.

The following is a minimal description of specific areas of accountability for a laser operator:

- Perform daily machine startup and shutdown procedures

- Stage raw materials at work center for day’s production

- Load and unload machine with correct sheet sizes and label parts with correct part numbers

- Report all equipment deficiencies to supervisor

- Ensure production schedule follow-through as allocated by Pre-Fabrication Manager and/or Engineering Manager

- Perform operator-level maintenance and cleaning of cutting equipment and work area in accordance with company standards and manufacture’s machine recommendations

- Check parts to ensure they are within tolerance of company standards

- Deburr parts that come off the laser

- Place materials that come off the laser and are deburred in the proper kitting box for each job

- Other duties as assigned

- Continuously lift 50 pounds

- Work at a fast pace

- Use and read a tape measure

- Know and use proper rigging techniques to load and unload machines

Applications are available on our website: https://www.southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to timbri@southernfabricationworks.com

Southern Fabrication Works, LLC is located in Burley, Idaho where we design and construct custom food processing equipment. We are currently seeking a Water Jet Operator. The water jet operator will primarily operate our water jets, cutting sheets of material into various parts, deburring the parts, and then ensuring they are put in the proper kitting box. Detail oriented, highly accurate, and the ability to communicate with coworkers, and management, as well as the ability to multitask and meet deadlines are essential.

The water jet operator works under the specific supervision, guidance, and direction of the Pre-Fabrication Manager, and the general supervision of the Owner.

Interested candidates will have experience operating a water jet, along with other power and hand tools, can accurately and precisely read a tape measure, and can read and understand blueprints and will have previous experience operating abrasive water jet cutting systems, and experience with nesting and programming software.

The following is a minimal description of specific areas of accountability for a water jet operator:

- Program, setup & operate waterjet cutting system.

- Safely load & unload material from waterjet table.

- Cleaning, deburring, finishing & packaging of finished goods.

- Operation of support equipment for drilling, tapping, tumbling, etc. as required for parts finishing.

- Troubleshoot & correct errors, faults or other conditions resulting in machine downtime

- Perform preventative maintenance on equipment - including cutting heads, pumps, drives, filtration equipment, garnet removal, etc.

- Responsible for overall safety, cleanliness & operational efficiency of the equipment.

- Identify & implement support equipment and technology solutions to streamline manufacturing operations & increase operational efficiency.

- Perform routine maintenance on machinery.

- Calculate dimensions and tolerances.

- Comply with internal quality checks.

- Understand mechanics of the equipment including high-pressured water system, pumps, and motors.

- Other duties as assigned

Applications are available on our website: https://www.southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to timbri@southernfabricationworks.com

Southern Fabrication Works is seeking a Saw Operator. The Saw Operator will primarily operate our bandsaw to cut stainless steel and tubing to exact measurements specified on the blueprints. Detail oriented, highly accurate, and the ability to communicate with coworkers, and management, as well as the ability to multitask and meet deadlines are essential.

The Saw Operator works under the specific supervision, guidance, and direction of the Pre-Fab Manager, and the general supervision of the General Manager.

Interested candidates will have experience operating a bandsaw, along with other power and hand tools, can accurately and precisely read a tape measure, and can read and understand blueprints.

The following is a minimal description of specific areas of accountability for a Saw Operator:

- Set up and operate a bandsaw

- Read and understand blueprints and/or job orders to determine specifications, such as material, type and size of stock, and dimensions to be cut

- Obtain and transfers materials to machine, manually or with a hoist

- Set saw blade angle to obtain desired angle of cut, using wrenches and other tools

- Ability to take extremely accurate measurements

- Keep a clean and safe work station

- Ability to operate a forklift

- Simple mathematical calculations

- Deburr material from laser and waterjet

- Provide backup to other areas in pre-fabrication as needed

- Other duties as assigned

Applications are available on our website: https://www.southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to timbri@southenrfabricationworks.com.

Southern Fabrication Works, LLC is located in Burley, Idaho where we design and construct custom food processing equipment. We are currently seeking a Laser Operator. The laser operator will primarily operate our laser, cutting sheets of stainless steel into various parts, deburring the parts, and then ensuring they are put in the proper kitting box. Detail oriented, highly accurate, and the ability to communicate with coworkers, and management, as well as the ability to multitask and meet deadlines are essential.

The laser operator works under the specific supervision, guidance, and direction of the Pre-Fabrication Manager, and the general supervision of the Owner.

Interested candidates will have experience operating a laser, along with other power and hand tools, can accurately and precisely read a tape measure, and can read and understand blueprints.

The following is a minimal description of specific areas of accountability for a Saw Operator:

- Perform daily machine startup and shutdown procedures

- Stage raw materials at work center for day’s production

- Load and unload machine with correct sheet sizes and label parts with correct part numbers

- Report all equipment deficiencies to supervisor

- Ensure production schedule follow-through as allocated by Pre-Fabrication Manager and/or Engineering Manager

- Perform operator-level maintenance and cleaning of cutting equipment and work area in accordance with company standards and manufacture’s machine recommendations

- Check parts to ensure they are within tolerance of company standards

- Deburr parts that come off the laser

- Place materials that come off the laser and are deburred in the proper kitting box for each job

- Other duties as assigned

- Continuously lift 50 pounds

- Work at a fast pace

- Use and read a tape measure

- Know and use proper rigging techniques to load and unload machines

Applications are available on our website: https://www.southernfabricationworks.com/careers/

Please submit a completed application with attached resume to Southern Fabrication Works Office, 238 West 35 South, Burley, Idaho or by email to timbri@southernfabricationworks.com.