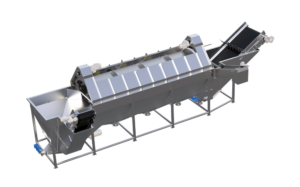

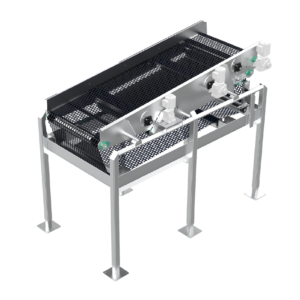

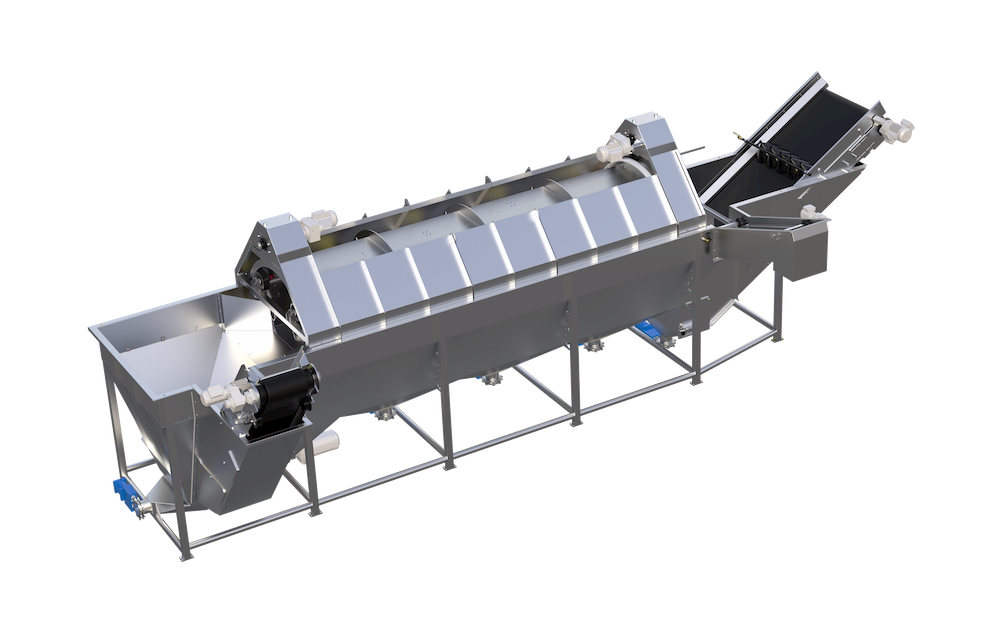

KW WASHER

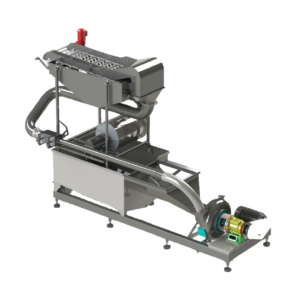

DESTONER COMBO

Used for de-stoning, washing and floating objects separation for tuberous and bulb-shaped products. The standard TM drum washing unit is characterized by a robust, dimple design whereby the product can be washed and de-stoned under an adjustable water level. Depend- ing on the wishes of the customer, the water can be removed at the discharge side of the drum using a mechanically-operated, or at extra cost,- a hydraulically-operate slide valve/sluice. The slide valve/sluice is to allow filling level control and the aggressiveness of the washing. It is also possible to install a mechanical drive system after the slide valve/sluice in order to remove floating objects. Using a circulating pump, you may, if so required, determine the life of the product in the drum, and as a result, you also have to provide less external water. A clean water spraying nozzle system on the discharge conveyor belt can ensure that a cleaner product emerges from the water. The entire assembly can also be designed with a fully automated adjustable water level in combination with automatic valves. The drum is suspended in a main- tenance-free belt construction with which all the rotating parts are placed well above the water level. The drum is made with one or two drives, depending on the amount of water.

BENEFITS

- 3 processes in one machine

- The intensity of the washing effect can be adjusted easily

- Robust, simple drive, slippage-free

- All the components are perfectly accessible for maintenance

- Very high capacities are possible compact overall dimensions

- Fewer wear-and-tear parts due to the combination

- One water inlet for the entire machine

- Low water usage

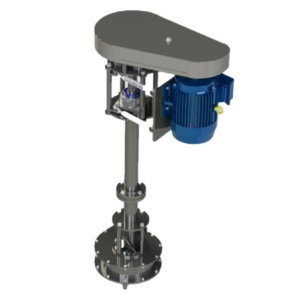

SPECIFICATIONS

| MODEL | KW-320-L/R | KW-450-L/R | KW-600-L/R | KW-700-L/R | KW-800-L/R |

|---|---|---|---|---|---|

| CAPACITY TON/HR | 15 | 40 | 60 | 100 | 150 |

| MEASURMENTS LxWxH (mm) | 2664x2503x2636 | 3575x3390x2815 | 5300x3900x3380 | 6800x4100x3800 | 10581x2839x4000 |

| FINISH | PICKLED STAINLESS STEEL 304 | ||||