Southern Fabrication Works

About SFW

Our History

Southern Fabrication Works struck its first arc in April 1998 as the owner, Neil Justesen, inaugurated his new company from a garage in Oakley, ID. Working heavily on field piping of steam and ammonia systems in the beginning, Neil combined his formal training in welding engineering with his formative training growing up as a handyman on ranching operations in Oklahoma and Florida. In a location in southern Idaho where weld shops are as common as gas stations, SFW grew rapidly and eventually acquired the former Idaho Metal Fab company, positioning years of experienced capability in the food processing industry as SFW's overarching business focus.

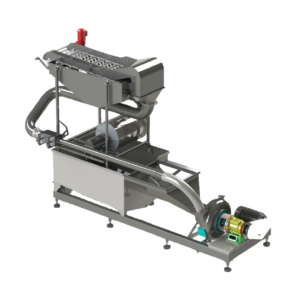

Powerful Technology

SFW continues with the water knife cutting technology pioneered by IMF with continual improvements to skid-mounted as well as modular cutting systems. SFW's cutting systems are used worldwide. The pioneering IMF automatic switcher, which switches out a plugged cutting block to maintain continuous cutting operations while the plugged block is cleaned and readied for service, has been updated into an upright ergonomic unit with operational redundant safety and reduced maintenance.

Wide range of equipment

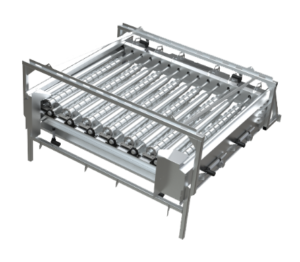

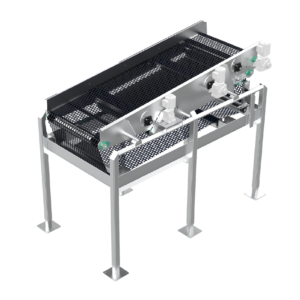

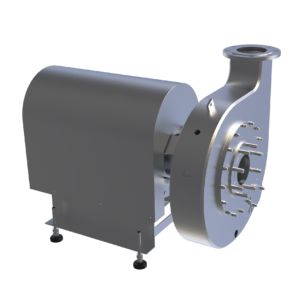

Other food processing equipment built by SFW includes wire mesh conveyors, modular belt conveyors, standard black belting conveyors, augers, tote dumps, pump tanks, pump stands, custom SS storage tanks, vacuum tanks, sizers, preheaters, scavenger reels, roller inspection conveyors, roller dryers, flumes, catwalking, and dewatering grizzlies.

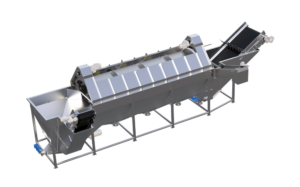

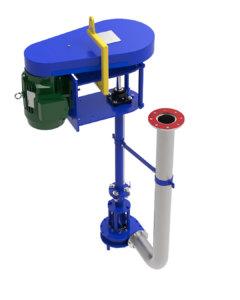

Tummers Rocktrap

SFW has partnered with Tummers Food Processing Solutions in Holland to build and distribute the Tummers rocktrap and rocktrap/washer to complete SFW's capability for complete receiving equipment solutions. The Tummers rocktrap actively separates rocks from product with a propeller induced water column that flumes the potatoes down the line while allowing heavier rocks to sink against the current and onto a submerged conveyor belt for removal.

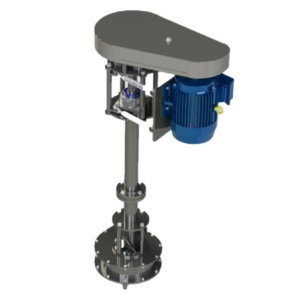

Custom Engineering

SFW also offers design and layout capability with its in-house engineering department. Utilizing SolidWorks software, equipment and layouts can be realized in 3D for customer planning and approval prior to construction.

Full Service

SFW's manufacturing capabilities includes a full-service machine shop, field crews, and large fabrication bays. Customers are encouraged to arrange for guided tours of the SFW facility to see firsthand why SFW is uniquely suited to provide custom-built solutions from custom-engineered designs all under one roof.