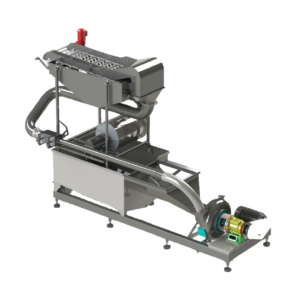

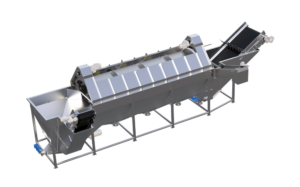

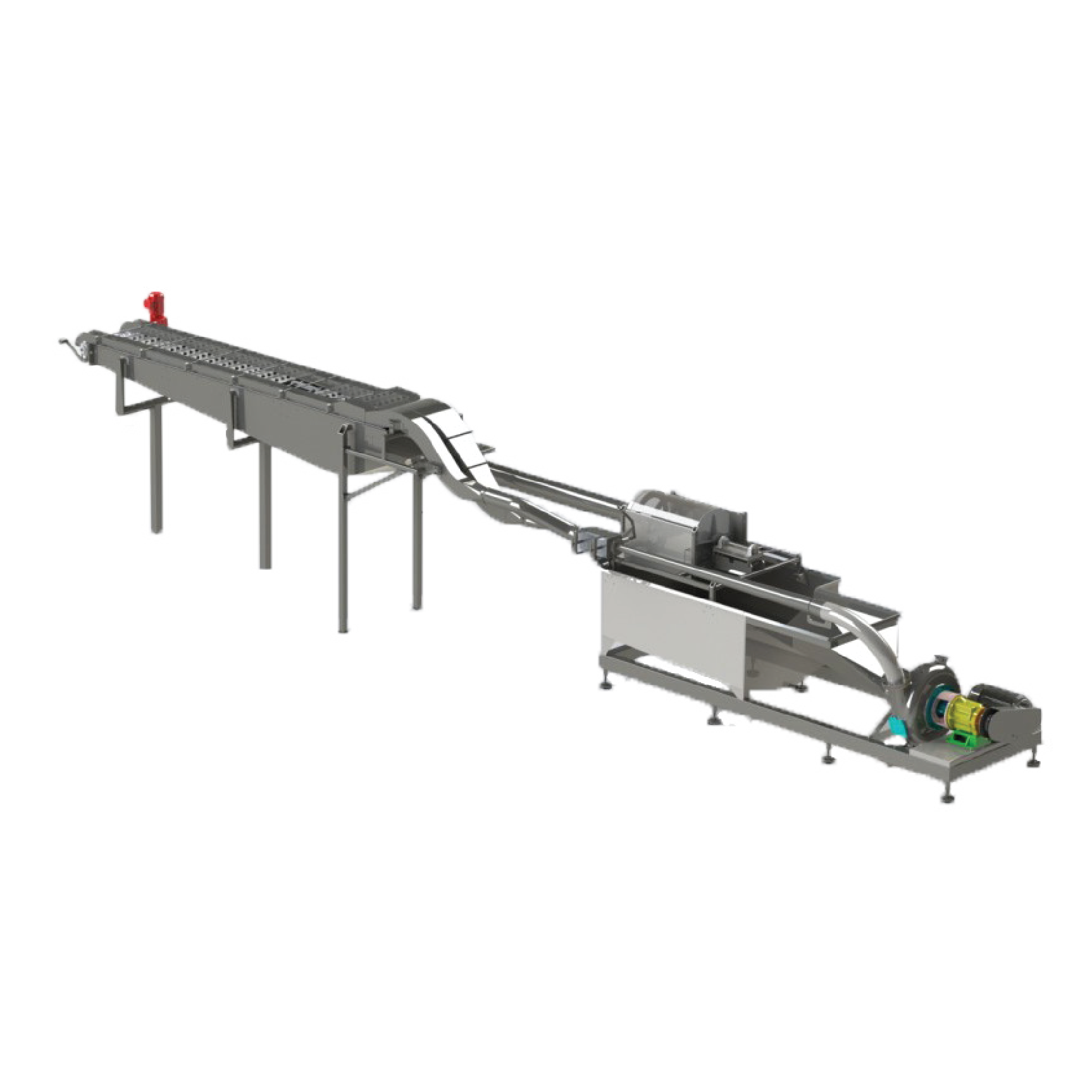

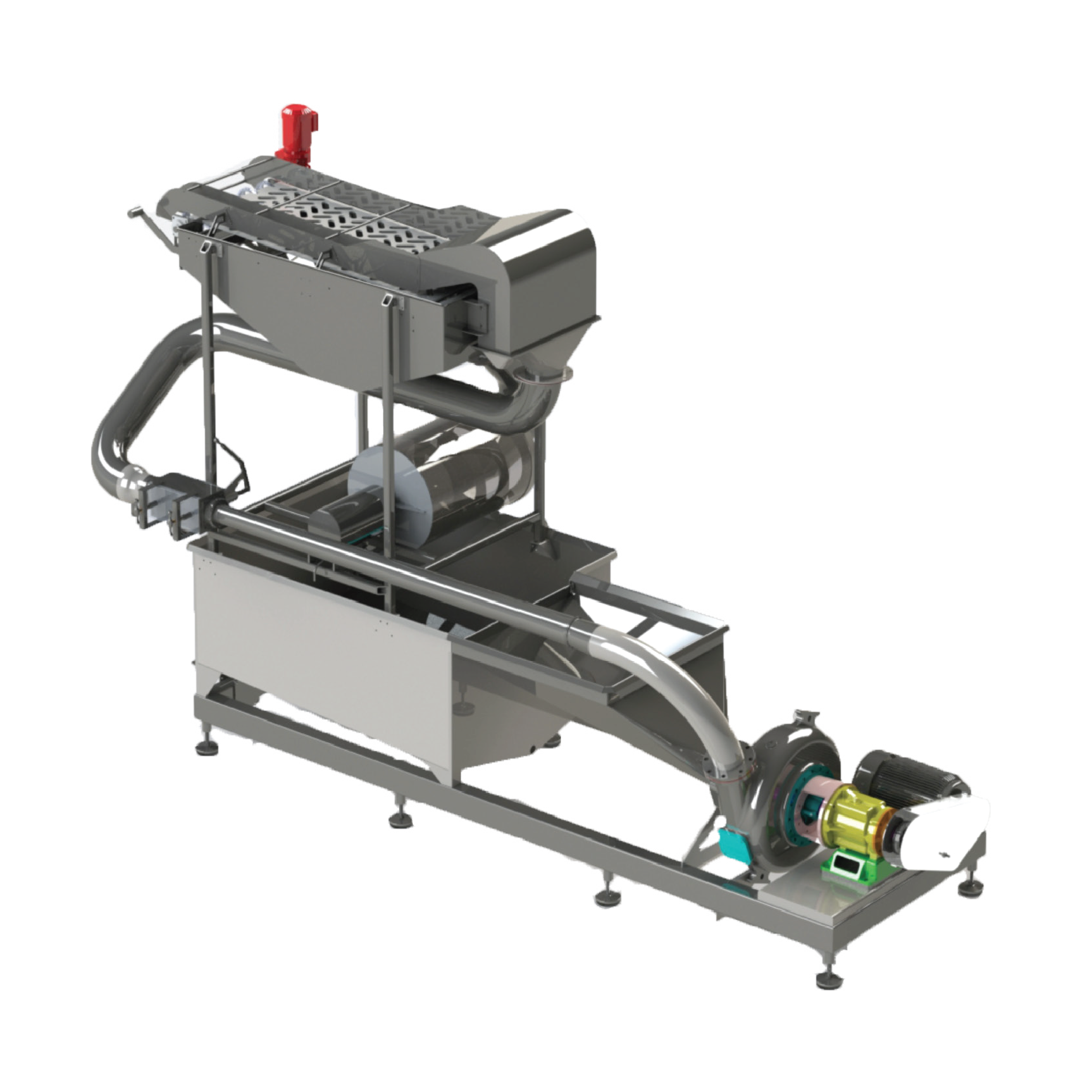

HYDROCUTTER

WHAT IS A HYDROCUTTER?

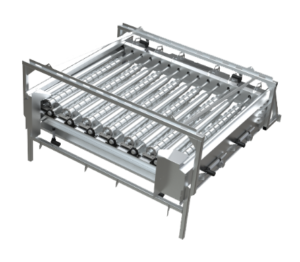

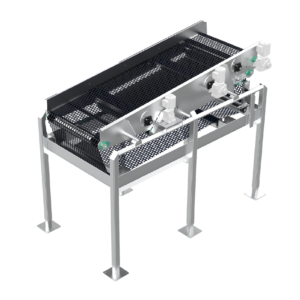

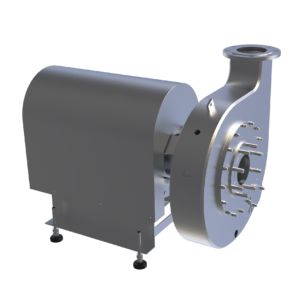

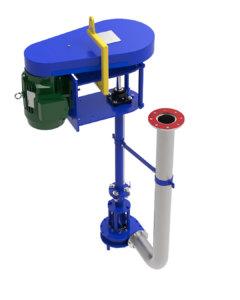

ELEVATE YOUR FOOD PROCESSING OPERATIONS

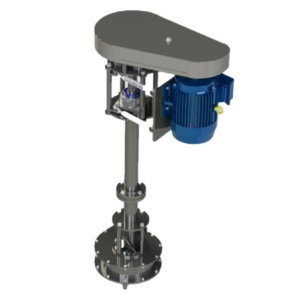

Incorporate the power of precision and efficiency into your food processing operations with the revolutionary hydrocutter technology. This industrial marvel harnesses the force of high-pressure water jets to deliver impeccable cutting and slicing results while reducing waste. With customizable water pressure, it's a versatile addition to your processing line. Moreover, the hydrocutter's unique ability to sanitize products during the cutting process ensures optimal hygiene standards.

Ready to experience the benefits of a hydrocutter and explore our custom food processing systems at Southern Fabrication Works? Contact us today to see how innovation and expertise can revolutionize your food processing operations. Don't miss the opportunity to elevate your business to new heights with our tailored solutions. Contact us now to get started